Start one step closer to the finish line

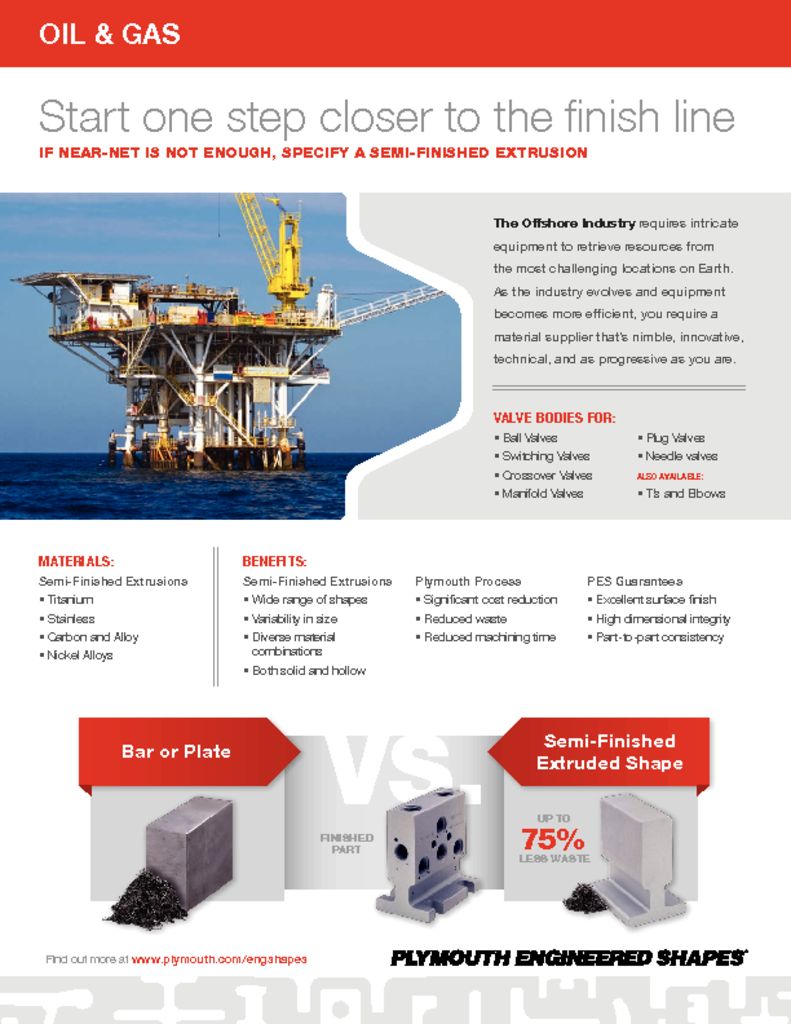

If Near-Net is not enough, specify a Semi-Finished Extrusion

The Offshore Industry requires intricate equipment to retrieve resources from the most challenging locations on Earth. As the industry evolves and equipment becomes more efficient, you require a material supplier that’s nimble, innovative, technical, and as progressive as you are.

VALVE BODIES FOR:

- Ball Valves

- Switching Valves

- Crossover Valves

- Manifold Valves

- Plug Valves

- Needle valves

Also Available :

- T’s and Elbows

Materials:

- Semi-Finished Extrusions

- Titanium

- Stainless

- Carbon and Alloy

- Nickel Alloys

Benefits:

- Semi-Finished Extrusions

- Wide range of shapes

- Variability in size

- Diverse material combinations

- Both solid and hollow

Plymouth Process

- Significant cost reduction

- Reduced waste

- Reduced machining time

PES Guarantees

- Excellent surface finish

- High dimensional integrity

- Part-to-part consistency

Our Company

No other manufacturer in North America offers so much experience in special shape technology, or provides so many value-added options to meet your product specifications as Plymouth Engineered Shapes.

Steel and Titanium extrusions provide advantages not offered by alternative methods such as forgings, castings, and machining from bar or plate stock. Economic advantages include minimal tooling costs, reduced material usage, lower parts count resulting from the ability to extrude complex shapes over length in a single operation and less downstream machining and finishing operations. The quality benefits of extrusion include improved surface quality and superior flatness and straightness, which is especially critical for long length structural operations.

Contact us today to discuss your product requirements and specifications. Our highly technical team of engineers is eager to assist you!

INDUSTRIES SERVED:

- Aerospace

- Commercial

- Boiler

- Oil and Gas

- Mechanical

- Nuclear

- Alternative Energy

- Energy – Power Generation

- Mining